Our company recommends using prefabricated reinforced products in construction. It ensures high cost effectiveness, analysis of which is presented below and proved by examples.

| Example 1. |

Monolith frame residential building. Height – 22 floors. Economy class. Total space – 16 thousand square meters*. |

|---|

Using prefabricated frames and products saves 23.8 million roubles, which makes up 6.4% of the estimated construction cost. It is proved by the figures presented in the table.

| Economic parameters |

Units of measurement |

Metalworking on the construction site |

Supply of prefabricated frames and other products |

|

Construction period |

days | 738 | 540 |

|

Total circulating capital |

thousand roubles | 34 452 | — |

|

Including the one related to: - own produced materials; |

thousand roubles |

425 |

— |

|

Cost of rebar fitters’ labour (10 people) |

тыс. руб | 4 356 | — |

|

Formwork (with 100 turnovers taken into account) |

thousand roubles | — | 1 600 |

|

Cage production cost |

thousand roubles | — | 17 002 |

|

Total expenses |

thousand roubles | 42 389 | 18 602 |

|

Total construction cost relative share |

% | 11,4 | 5 |

| Example 2. |

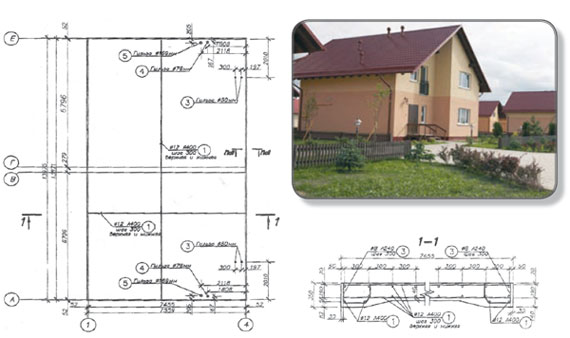

Construction of a private residential building |

|---|

For reinforcement of residential building basement (10 303 m x 7 559 mm) it is recommended to use reinforcement workpieces (d=12 mm) in two levels, or meshes and cages. Comparative analysis of these variants is presented in the table. Prices are relevant as of 2009.

| Option 1 (reinforcement with reinforcement workpieces, or rebars) (армирование штучной арматурой) |

Option 2* (reinforcement with prefabricated meshes and cages) |

| Rebars – 24 204 roubles | Reinforcement meshes, cages – 21 881 roubles |

| Steel cutting and bending, cage assembly and welding – 12 344 roubles | Framework assembly using reinforcement meshes and cages – 6 172 roubles |

| Total: 36 548 roubles | Total: 28 053 roubles |

* А 500 rebars are the best option to be used in reinforcement. Such rebars ensure the best cost benefit

To reduce construction costs, prefabricated cages and meshes are used for reinforcement. Variant 2 shown in the table proves high cost benefit of this option.

Basement reinforcement plans.

Standardized reinforcement meshes and cages, when used in construction of various buildings, ensure high cost benefit due to:

Using standardized quality-manufactured reinforcement products (reinforcement meshes and cafes, rebar cages) reduces costs, increases performance, improves constriction quality, and reduces construction time.

Many modern construction companies have to organize reinforcement tying sites on the construction field to make welded reinforcement products. It leads to increase in construction costs due to the need to do the following:

Also, reinforcement tying site performance is worse than automatic processing lines.

Field reinforcement mesh and cage production lowers the quality of products. It happens due to failure to meet the construction parameters stated in the design, usage of low-quality reinforcement products, welding errors and faults, in other words, all those issues that are unacceptable when constructions are prefabricated.

Analysis of field-made welded construction junctions made with radiographic and ultrasonic examinations revealed that around 75% of products were defect. Also, construction companies very often use manual cage tying, which leads to considerable increase in installation of reinforcement labour efforts.

Prefabricated welded reinforcement meshes and cages, when used in construction, do not only ensure good economic performance, but also make the construction process more eco-friendly. It is due to the fact that no reinforcement tying site is needed. Welding leads to atmospheric gas pollution and high-intensity light. Besides, such an approach lowers noise level and reduces production waste amount. All these advantages have a beneficial effect on the ecological situation and atmosphere.